Dual Fuel Kit

EMS TECH offers innovative retrofit technology to convert high speed diesel engines to operate reliably and efficiently in dual fuel mode, i.e. typically with 25% diesel fuel and 75% natural gas, or other gaseous fuel.

No internal modifications to the diesel engine are required; the standard compression ratio and pistons etc. are retained.

A comprehensive range of key components, allowing each system to be tailored to meet individual customer requirements is prepared for each conversion. The system automatically compensates for variations in gas quality and availability and will continue to function as a pure diesel engine if the gas supply is interrupted. This allows for maximum utilisation ofthe most cost-effective gaseous fuels and tarriffs.

This kit is an inexpensive method to get an existing high speed diesel engine running on dual fuel and significantly reducing fuel costs while retaining the full output power and flexibility of the original engine.

The larger the engine and the higher the annual running hours, the shorter the payback period will be.

Return of Investment: Can often be less than 6 Months

The Benefits

• Save money with cheaper fuel

• Simple conversion is cost effective

• Low pressure gas compatible

• 100% power with diesel or dual fuel

• Fast response time

• Improved dynamic performance

• Running clean gas can extend service intervals

Individual components of the system include:

Antiknocking control:

Genset Controller:

a highly configurable gen-set controller designed to handle a broad range of critical and complex parallel applications, including multiple Mains and CHP systems. It includes an internal load sharing unit that allows simple implementation of Multiple Prime Mover applications. PLC functions (including PID blocks) are available in this unit.

Temperature Control Module:

Monitors the exhaust temperatures and signals to the panel if diesel fuel needs to be increased to cool the combustion chamber.

Antiknocking control:

Each individual cylinder is monitored and protected against knocking.

Vibration Sensor:

Measures vibration frequencies to coordinate with the controller to ensure smooth, efficient and safe operation of the genset.

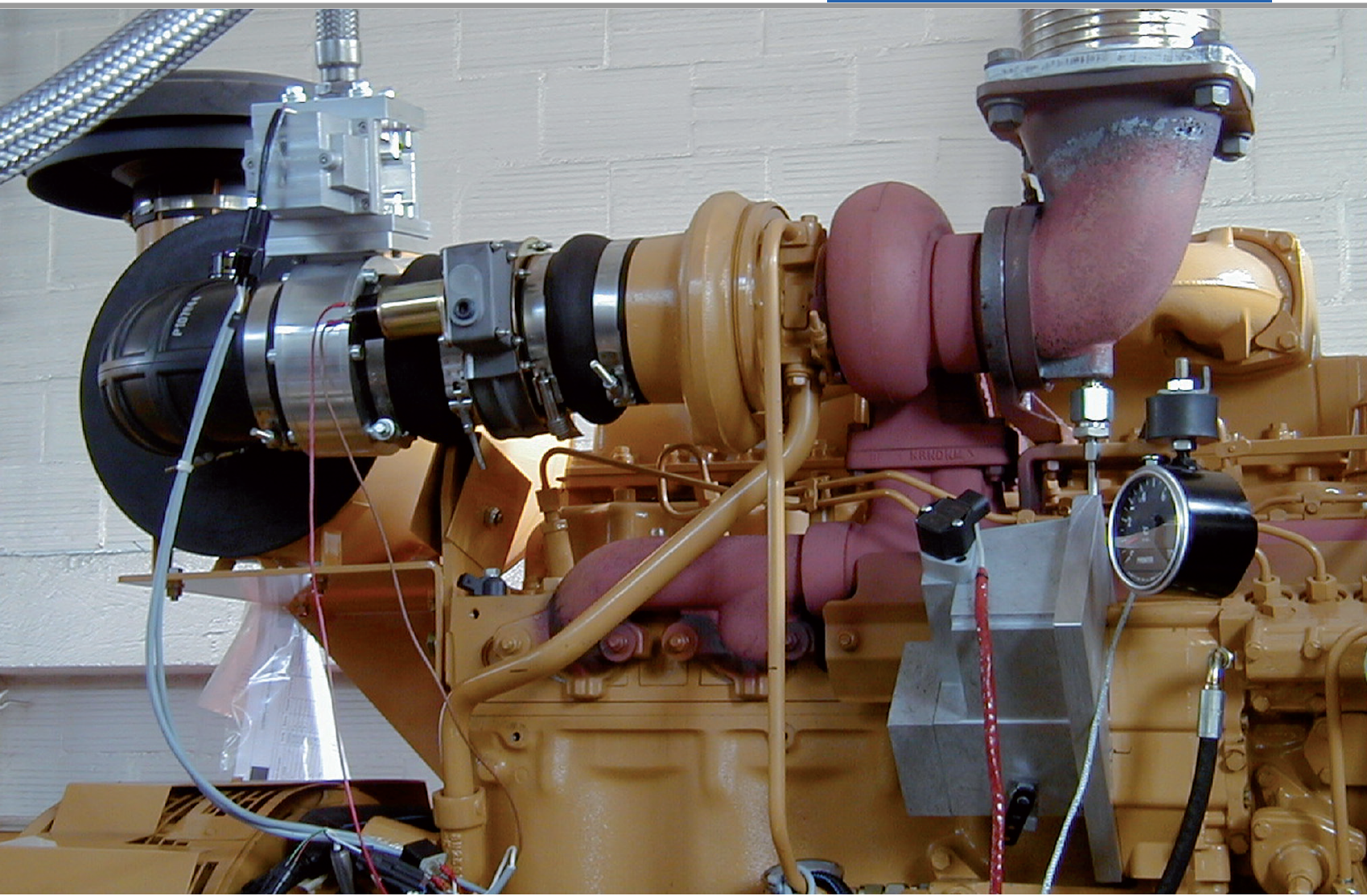

Gas flow actuators:

Designed for precise efficient metering of gas flow. The actuator is mounted directly to the mixer and features a proportional

electromagnetically driven throttle plate. Two internal return springs make this a normally-closed fail-safe design.

Air gas mixer:

Designed specifically for dual fuel systems. It can be adapted to fit a wide range of induction system diameters and the internal gas inlet tube can be optimised on-site.